STI SP001 Aboveground Storage Tank Inspections

Services

STI SP001 Aboveground Storage Tank Inspections

Welcome to Hugh’s Mechanical Equipment, LLC, your trusted partner for all your Aboveground Storage Tank (AST) inspection and compliance needs. We understand that state and federal regulations require periodic testing and inspection of ASTs, including adherence to the industry-standard Steel Tank Institute (STI) SP001 Inspection.

At Hugh’s Mechanical Equipment, LLC, we specialize in determining the ideal AST compliance standard for your facility and offer comprehensive STI SP001 Inspections. Our team of experts is well-versed in the requirements outlined by the Steel Tank Institute, ensuring that your ASTs meet the necessary criteria for continued service.

The STI SP001 standards focus on assessing the integrity of ASTs operating at atmospheric pressure of 1 psig. These inspections are specifically designed for ASTs that store stable, flammable, and combustible liquids, although they can be adapted for ASTs containing other substances after a thorough evaluation.

Our services cover a wide range of AST configurations, including steel single and double-walled tanks, steel diked tanks, concrete exterior tanks, and portable containers like drums and totes. Additionally, we extend our expertise to field-erected ASTs with a maximum shell height of 50 feet and a maximum diameter of 30 feet, which translates to approximately 264,000 gallons of capacity.

How often do I need to have my Aboveground Storage Tank Inspected?

Discover the optimal inspection frequency for your Aboveground Storage Tanks (ASTs) with our STI SP001 Inspection services. At our company, we understand that compliance with STI SP001 Standards necessitates tailored testing and inspections based on factors such as container size, configuration, and design.

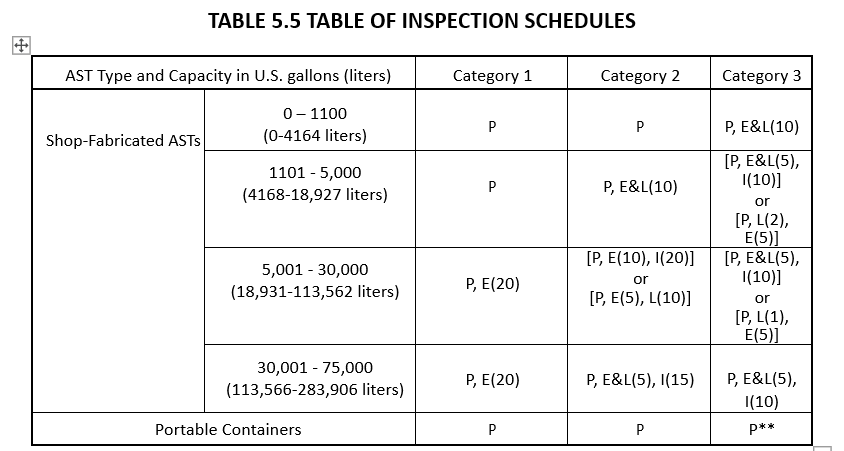

Our approach is guided by the risk-based inspection matrix provided by the standards (Table 5.5). This matrix categorizes tanks into three risk categories, considering tank configuration, containment, and spill protection criteria. Category 1 represents the lowest risk, while Category 3 presents the highest risk. By combining these risk categories with tank size, we can determine the appropriate inspection frequency and method to ensure compliance with both your SPCC Plan and STI SP001 Standards.

Let’s explore the categories:

Category 1: ASTs with Spill Control and CRDM (Continuous Release Detection Method)

Category 2: ASTs with Spill Control, but without CRDM

Category 3: ASTs without Spill Control Based on the identified category, inspections may involve several types of assessments:

P: Periodic Inspection (Monthly)

E: External Inspection

L: Leak Test

I: Internal Inspection

Category 2: ASTs with Spill Control, but without CRDM

Category 3: ASTs without Spill Control Based on the identified category, inspections may involve several types of assessments:

P: Periodic Inspection (Monthly)

E: External Inspection

L: Leak Test

I: Internal Inspection

**Owner shall either discontinue use of portable container for storage or have the portable container DOT (Department of Transportation) tested and recertified per the following schedule (refer to Section 9.0):

Plastic portable container – every 7 years

Steel portable container – every 12 years

Stainless Steel portable container – every 17 years

Steel portable container – every 12 years

Stainless Steel portable container – every 17 years

Our experienced team is well-versed in these inspection requirements and will collaborate closely with you to develop a customized inspection plan. By adhering to the STI SP001 Standards and your specific needs, we ensure the integrity and compliance of your ASTs.

Contact us today to learn more about our STI SP001 Inspection services and let us help you establish an inspection schedule that aligns with industry standards and regulatory compliance. Trust in our expertise to maintain the reliability and safety of your Aboveground Storage Tanks.

- Fuel Oil Tank Installation and Removal

- Hugh's Mechanical Equipment LLC

- 304 Jobs Hill RD

- Ellington, Connecticut

- 860-454-8241